producing requires are evolving quickly, demanding precision and effectiveness to remain competitive. one particular vital area driving modernization is using personalized fixtures and jigs in output website procedures. These critical tools make sure the precision and effectiveness of manufacturing traces, particularly when personalized to specific marketplace needs. By integrating custom remedies, corporations can satisfy distinctive creation issues although attaining greater high-quality and maximizing output. This website explores how customization in fixtures and jigs is reshaping manufacturing and highlights its Added benefits for precision industries.

Table of contents:

Tailoring Fixtures to unique manufacturing prerequisites

the entire process of coming up with tailor made Jigs for specialised Tasks

advantages of Collaborating with companies for custom-made alternatives

genuine-environment Examples of personalized Fixtures maximizing efficiency

Tailoring Fixtures to particular manufacturing specifications

Fixtures are integral to ensuring that parts continue being fastened and effectively aligned during the manufacturing method. Tailored fixtures are designed with unique output needs in your mind, adapting to exceptional merchandise Proportions, workpiece steadiness demands, and operational demands. such as, companies while in the automotive or aerospace sectors trust in highly specialized fixtures to control complex assembly processes whilst sustaining tolerances inside of microns. These customizations be certain that Each individual generation phase is repeatable and precise, getting rid of problems that may compromise top quality or security. With precision mechanical areas getting to be the benchmark for high-executing industries, tailored fixtures function the backbone in their functions.

the whole process of building customized Jigs for specialised jobs

personalized jigs are invaluable when manufacturing traces have to have constant precision and efficiency. the method starts with being familiar with the manufacturing demands and operational problems confronted by a business. By conducting a detailed structure consultation, companies can build jigs that simplify sophisticated creation steps when lessening cycle occasions. whether or not for drilling, chopping, or assembly, custom-made jigs bring regularity to substantial-quantity manufacturing environments. They may be normally fabricated making use of long lasting products like metal or aluminum, capable of withstanding extended manufacturing runs without the need of compromising performance. Highly developed production systems such as CAD software package or 3D modeling more streamline the design method, making sure the jig integrates seamlessly into current workflows. The result? extremely economical creation lines that execute jobs with unparalleled accuracy.

great things about Collaborating with brands for custom made methods

selecting to customise fixtures and jigs unlocks a range of advantages for brands planning to remain aggressive. To start with, customization maximizes operational performance, as personalized solutions align flawlessly with the requirements of your production line. Secondly, collaboration with knowledgeable makers assures specific substance assortment and design and style, translating to strong factors that happen to be created to past. Last of all, tailor made options make it possible for for more quickly production cycles and decreased downtime, as equipment and tooling are optimized for smooth functions. participating trustworthy companions like Shenzhen Yongxinglong Industrial progress Co. for tailor-made jigs and fixtures makes certain superior product high quality as a result of specialist craftsmanship and Innovative output methods. By Doing work carefully with these specialists, businesses also get usage of chopping-edge innovations that make improvements to extensive-term functionality.

true-planet Examples of personalized Fixtures boosting productiveness

functional purposes of tailor made fixtures and jigs display their critical job in modern day generation devices. For instance, Shenzhen Yongxinglong collaborates closely with automotive and electronics producers to generate specialised welding fixtures. These fixtures make sure seamless alignment of auto components in the course of automatic welding functions, resulting in more powerful bonds and minimized assembly errors. likewise, personalized jigs for electronics manufacturing revolutionize precision assembly, enabling flawless placement of micro-parts. These advancements assist enterprises meet stringent sector requirements by reaching steady precision. By incorporating custom made styles, industries such as aeronautics and large machinery have the ability to decrease cycle situations considerably, maximizing each productivity and profitability.

Customization in fixtures and jigs manufacturing is an essential investment for industries in search of excellence. Tailored options from skilled companies like Shenzhen Yongxinglong Industrial enhancement Co. unlock unparalleled precision and efficiency, guaranteeing firms can fulfill their output goals though maintaining a aggressive edge. From minimizing cycle periods to improving products quality, the advantages of tailored fixtures and jigs are undeniable. are you presently ready to elevate the effectiveness of one's production line? Get in touch with Shenzhen Yongxinglong to learn more about how their high-good quality jigs and fixtures can meet your exact needs.

Tiffany Trump Then & Now!

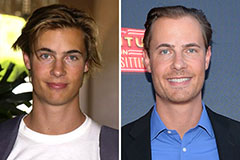

Tiffany Trump Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now!